Shipping quickly globally means shipping by air. Every 24 hours, more than 140,000 tonnes of cargo will be transported, equating to 657 million packages worth 17.8 Billion USD. To ship this much air cargo, it takes a massive amount of aircraft ULDs to get the consignments safely from one destination to the other.

When you ship goods by air you are most likely using a ULD (Unit Load Device), but what is that? An aircraft ULD is a device for grouping and restraining cargo, mail and baggage for air transport. It is either an aircraft container or a combination of an aircraft pallet and an aircraft pallet net. Aircraft ULD is designed to be directly restrained by the aircraft Cargo Loading System (CLS). And because the aircraft CLS directly interfaces with the aircraft ULD, the unit load device becomes part of the aircraft’s structure during flight and is therefore regulated, as any other aircraft component, in order to ensure flight safety under all foreseeable circumstances. The design, testing, manufacturing, operations as well as maintenance and repair of the unit load device are all subject to the safety and airworthiness requirements from the civil aviation authorities.

Aircraft ULD has been contributing to the safety and efficiency of the air transport industry since its birth in the late 1950s, however, like an unsung hero its contributions went unrecognized across the industry until IATA announced the initiative to reposition ULD as its core cargo activity at the 2010 World Cargo Symposium (WCS) followed by the launch of the 1st Edition of the IATA ULD Regulations (ULDR) in 2013 and the promotion of the IATA ULD Safety Campaign since 2016. Today, the ULD profile has been greatly increased industry-wide and the awareness of the critical relationship between safe ULD operations and flight safety as well as safety responsibilities has been widely raised across parties involved and from top management to frontline operational staff.

ULD container build-up is considered aircraft pre-loading, therefore, one of the main purposes of using aircraft ULD is to allow consignments to be unitized and grouped at the cargo warehouse hence eliminate greatly the manual loading and unloading of aircraft.

The use of unit load devices also effectively protects the contents loaded from loss and damage.

The design of the aircraft ULD contours maximizes the use of aircraft contours.

The use of unit load devices facilitates fast and easy transfer of the ULD and the contents loaded from one aircraft to another and even from one mode of transport to another.

The special purposes aircraft ULD such as Temperature-Controlled Container (TCC), Fire Resistant Container (FRC), Fire Containment Cover (FCC), horse stall, cattle stall, Garment on Hanger (GOH), etc., facilitate the transport of special cargo by air.

However, the most important purpose of unit load devices is to secure the loads throughout the flight from take-off to landing and especially during turbulence, which is similar to the purpose of the passenger seat belt. If the loads were not secured and restrained during flight, not only would they damage the aircraft but also the load shifting might impact the aircraft weight and balance and hence cause the loss of control of the aircraft.

There are various types of special purpose unit load devices including the certified horse stall (typical ULD Type Codes such as HMA and HMJ). Every day 200 racehorses are transported globally in aircraft ULDs. But bulk and loose items are also shipped in unit load devices. Global air cargo shipping has increased with e-Commerce giants like Amazon and Alibaba-Cainiao at the forefront. Amazon ULDs are a perfect example of packing bulk items and unitizing small online order packages for a single shipper. While Amazon ULDs are transported on Prime Air aircraft, their example is still relevant. It is how they are able to maintain their 1 and 2-day prime delivery, showing how effective shipping by air actually is. Many global companies utilize shipping by air and thereby unit load devices to ship perishables such as fruits and vegetables, seafood, flowers, time and temperature sensitive healthcare products such as vaccines and other pharmaceuticals, not to mention the air mail services for letters and express parcels provided by the postal operators around the world and so much more that needs quick and safe delivery.

Since majority of today’s ULD operations have been either performed by or outsourced to third parties such as Freight Forwarders and Ground Service Providers, quite often off-airport and completely outside the airline’s direct supervision, ULD is probably the only aircraft component that leaves the control of the airline and returns back after passing through many non-airline parties and has an impact on flight safety.

Airworthiness certification of a given type of aircraft ULD is obtained by the unit load device manufacturer from the airworthiness authority of the governing Civil Aviation Authority (CAA) approving that the ULD container meets the required minimum performance standards for installation aboard an aircraft. The approval can in principle be obtained under different procedures in compliance with the detailed requirements listed in, e.g. U.S. FAA 14CFR Part 21, European EASA Part 21, or the Chinese CCAR-21.By far the most commonly used procedure for aircraft ULD certification is the Technical Standard Order (TSO) approval, e.g. TSO-C90, ETSO-C90, or CTSO-C90, materialized by issuance to the ULD container manufacturer of a TSO Authorization. It must be noted that the certification process is conducted solely between the ULD container manufacturer and the applicable regulatory authorities such as FAA and EASA. Mutual recognition of certification standards and procedures is dependent on the various bilateral agreements between regulatory authorities.

Certified aircraft ULDs are regarded as removable aircraft parts, structurally capable of fully restraining their load and providing adequate protection to the aircraft systems and structure during flight. However, due to the increasing industry trend of operations moving upstream to shippers and freight forwarders and outsourcing to ground service providers, more and more non-airline parties are involved in unit load device handling but without proper understanding of the ULD safety awareness; aircraft ULDs were quite often treated as packaging materials or cheap handling equipment. Therefore, one of the key messages the IATA ULD Safety Campaign aims to spread across the industry is that ‘ULDs are aircraft parts and are critical to flight safety’.

While the airworthiness certification of aircraft ULD covers the initial airworthiness requirements that a ULD container manufacturer must meet, it must be clarified that maintaining the continued airworthiness conditions of the aircraft ULD during daily operations should be the responsibility of all the parties involved.

View a few examples of certified ULD containers

Established by and under the governance of the IATA Cargo Services Conference (CSC), the IATA ULD Board (ULDB) is responsible for the development of standards, recommendations and procedures concerning the specifications, handling, restraint and maintenance of ULDs and to promote the worldwide recognition, adoption of and adherence to those standards and procedures. The main source of IATA ULD standards is the IATA ULD Regulations (ULDR), which is updated annually by the ULDB in consultation with the industry stakeholders.

Safety is always the No. 1 priority, but due to the massive loads being handled with aircraft ULDs and how often they change hands, strict protocols must always be followed. Not only for the safety of the passengers, crew, and aircraft but also for the occupational health and safety of the personnel handling the loads as well as for maintaining the consignment's integrity. IATA's ULD Regulations Manual gives the most current guidelines to help stakeholders stay up-to-date.

Each year unit load device repairs cost the industry $330 million, with 80% of the damages being avoidable with proper handling. Taking the necessary time and attention to properly handle aircraft ULDs with care should always be a priority. Not only can mishandling damage the goods being shipped by air, but also the incorrect handling of ULDs has been the leading cause of aircraft damage during ground operations .

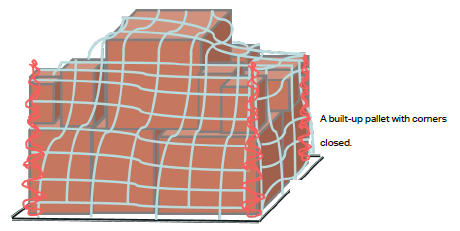

The build-up of the unit load device is crucial to its integrity. The operators must make sure it is the proper size, type, without damage, and structurally suitable for shipping as well as clean. When loading the goods onto the aircraft ULD (ULD build-up), they should be interlocked, less likely to shift in transit. If this is not possible, then the load should be properly held in place with ropes or straps underneath the pallet nets.

It is necessary to place heavier items at the bottom and lighter items towards the tops to maintain a proper sense of gravity. The operator should take special care with items of odd shape or sizes that do not conform to the packing of other items to ensure they are properly secured to avoid shifting during transport.

Any party that needs to store a ULD, whether short or long term, is responsible for providing and operating suitable and sufficient storage infrastructure to prevent ULD container damage. ULD owners shall ensure that the number of ULDs at any location do not exceed the quantity necessary for their current operational requirements, and that overstocked or damaged units are removed without delay. All organization whose function involves moving ULD into or out of storage facilities shall be equipped with adequate equipment and employ staff with required training and qualifications to perform such function.

It is worth noting that proper ULD facilities and equipment in compliance with ULDR shall NOT be considered as costs of implementing ULDR but the costs of doing business.

Because safety is always the number one concern during flight, assuring the airworthiness of all unit load devices is a priority. For this reason, a complete ULD serviceability check should be conducted prior to ULD build-up when the ULD is empty by checking all the ULD components listed on the ULD Operational Damage Limits Notice (ODLN).

Once confirmed serviceable after a complete ULD serviceability check and once a ULD is built up, regular visual checks for any visually detectable damages to ULD components should be performed in the course of ULD operations to ensure the serviceability of a unit load device is continuously monitored and verified.

ULD regulations are the basis for standardized global operations and handling guidelines of all unit load devices. It is essential that no matter what airline, what airport, what freight forwarder is handling an aircraft ULD, the strictest safety regulations are consistently being followed.

The ULDR contains both technical and operational standard specifications and regulatory requirements as well as airline requirements applicable to overall ULD operations. It is one means of compliance and a consolidated reference manual containing a single set of regulations for all parties involved conforming to all legally applicable and industry agreed regulations.

Applying IATA regulations ensures that no matter where you are or who you are working for, the most current, strictest safety regulations are being followed. IATA goes over and beyond applying every standard.

The Operator, or in this case the Carrier, has specific responsibilities when handling unit load devices. The 18 particular criteria are outlined in the ULD Regulations Manual. It is important to note that even when subcontracted out to other parties, it is still the Operator's responsibility to oversee the proper handling of the unit load devices. The Carrier must also publish and keep on hand an Operations Manual and make it available to the ground handling contractors. It is also the Carrier's responsibility to report any and all incidents to the Operator's Quality Control department for investigation and to be analyzed so that corrective action can be taken.

According to the ULD Regulations Manual, operators must have a Safety Management System in place that:

Other parties involved in one or more function(s) of ULD handling has the responsibilities outline below:

There are specific limitations that must be met when loading ULDs. One of these is the aircraft's certified structural capability. Another is the maximum gross mass or Maximum Gross Weight (MGW) of a unit load device in its given position in the aircraft's cargo compartment. Then there is also the area load limitation, linear load limitation, centre of gravity, cargo loading system (CLS), and aircraft contour limitations. There is a lot to take into consideration when loading unit load devices safely onto an aircraft.

The general classifications for ULDs per the ULD Regulations Manual are as follows:

The Compartments Classifications determine which deck the unit load device will be installed aboard aircraft.

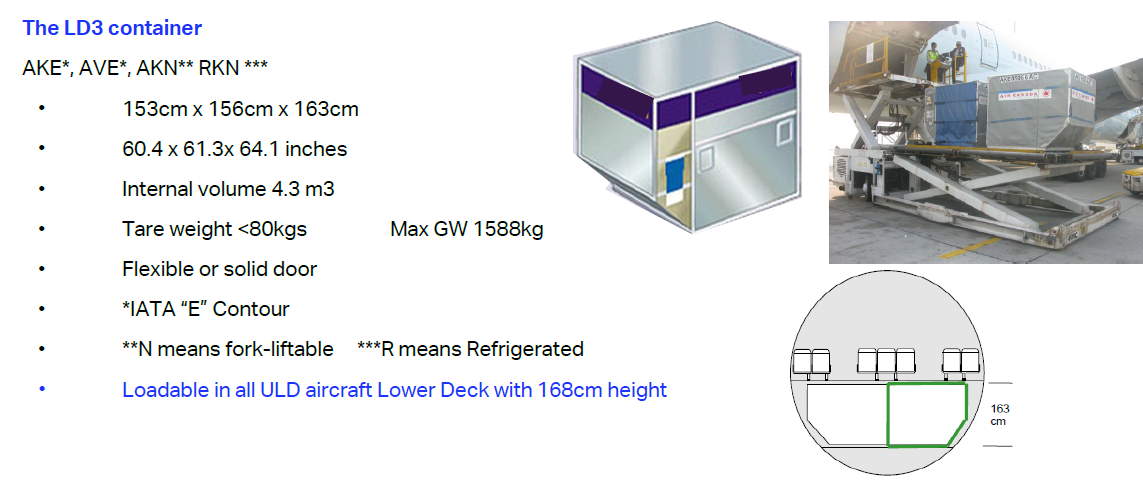

IATA's Identification Code for ULD gives each ULD a unique identification that makes it easy to exchange information contained in the markings. The IATA ULD ID Code consists of 9 or 10 characters, of which the first 3 positions form the ULD Type Code, followed by the four or five characters of ULD serial number, and ended with the two-character ULD owner code. The code letters in the ULD Type Code have their specific descriptions, e.g. in the ULD Type Code ‘AKE’, ‘A’ in Position 1 indicates the ULD Category as ‘Certified aircraft container’, ‘K’ in Position 2 indicates the Base Dimensions of ‘1,534 × 1,562 mm (60.4 × 61.5 in), and ‘E’ in Position 3 indicates the container contour.

Regarding specifications of a unit load device, there are technical and operating specifications. The technical specifications refer to design and airworthiness, test requirements for ULD and accessories to meet flight safety standards.

ULD operating specifications relate to the best practices for operations according to the Civil Aviation requirements and International standards and minimize costly unit load devices and aircraft damage.

ULDs are marked according to the IATA Cargo Services Conferences (CSC) Resolution 685, which states that, with the exception of the Identification Code, all markings must comply with the IATA ULD Regulations SS 40/0. The markings show ownership, give essential information, and facilitate the easy exchange of information upon transfer.

Proper documentation is always required at every juncture of the transport process. The ULD Regulations state the minimum required documentation, which defines the regulatory flight safety requirements that apply to all aircraft ULDs and must be readily available at sites preparing unit load devices for aircraft loading.

As mentioned before, majority of today’s ULD operations have been either performed by or outsourced to non-airline parties such as Freight Forwarders and Ground Service Providers, it has become one of the most challenging tasks to manage and control such returnable asset while ULD has to be frequently transferred from one party to another during daily operations and quite often off-airport and completely outside the ULD owner’s direct supervision, not to mention the difficulty in clarifying the liability for loss or damage of ULD. In order to solve such industry problem, the improved ULD Control Receipt (UCR) has been developed in both paper and electronic form and included in the ULDR Documentation section. It is highly recommended that when a ULD container is transferred, the Transferring Party shall provide the UCR and the Receiving Party shall, once verified, countersign and confirm the UCR. It must be noted that the party in possession of the ULD shall assume full responsibility to the ULD owner for the serviceability of the unit load device.

The handling guidelines for unit load devices cover continuing airworthiness, storage, transport and movement, transfer, build-up and break-down as well as special purpose ULD, which are intended for any organizations and personnel performing any function involving the ground handling of aircraft ULD.

IATA ULDR requires properly planned and maintained initial and recurrent training programs for all persons involved in ULD operations or ULD management. Appropriate unit load device training shall be provided in the requirements commensurate with the functions and responsibilities for all personnel, regardless of their being employed by the airline or a non-airline organization such as Ground Service Providers and Freight Forwarders.

In addition, training requirements have been reflected in the IOSA, ISAGO, Airport Handling Manual (AHM) and recently the Cargo Agency Conference Resolutions Manual (CACRM).

Moreover, there has been increasing regulatory oversight on safe ULD operations (FAA, EASA, UK CAA, Australian CASA, etc.), and for example, the FAA in the revision of its Advisory Circular (AC) 120-85 on ‘Cargo Operations’ emphasizes the importance of training requirements for personnel including non-airline parties (‘vendors’) involved in ULD operations.

Despite the clear industry guidance and regulatory requirements, the question about ‘Why is ULD training necessary’ is still raised from time to time. A much simpler answer could be:

Therefore, another key message delivered by the IATA ULD Safety Campaign is that ‘Every stakeholder must commit to its safety responsibility and ensure training requirements are met’.

In short, being properly trained allows for fewer mistakes and smoother transitions in air cargo logistics. Ensuring industry-wide safety regulations are being strictly followed could reduce ULD-related costs by $475 million. IATA offers training such as ULD Operations, Cargo Warehouse Ops, ULD Train-the-Trainer and more needed to remain up-to-date on all regulations needed to properly handle unit load devices for air transport.

Aircraft ULDs provide safe travel for your goods to be shipped by air. Following IATA regulations means meeting global safety standards to keep the integrity of the goods while ensuring aircraft, crew, and passengers all arrive at their destination safely. Go to IATA.org to find more information about the ULD Regulations Manual and others.